WHAT IS PLASTIC?

Plastics are a wide range of synthetic or semi-synthetic materials, that usually use polymers as a main ingredient. The plasticity during production makes it possible for plastic to be moulded, extruded or pressed into solid objects of various shapes, making them an adaptable material for many different uses. This adaptability, plus a wide range of beneficial properties, such as being light weight, durable and flexible, alongside cheap production processes has led to widespread adoption in contemporary society. Plastics typically are made through human industrial systems; most modern plastics are derived from fossil fuel based petrochemicals like natural gas or petroleum; however, recent industrial methods use variants made from renewable materials such as derivatives of corn or cotton.

Plastics have many uses throughout society. In developed economies, about a third of plastic is used in packaging and roughly the same in buildings in applications such as piping, plumbing or vinyl siding. Other uses include automobiles (up to 20% plastic), furniture, and toys. In the developing world, the applications of plastic may differ, 42% of India’s consumption is used in packaging. For example, in the medical field as well, with the introduction of polymer implants and other medical devices derived at least partially from plastic. Worldwide, about 50 kg of plastic is produced annually per person, with production doubling every ten years.

The world’s first fully synthetic plastic was Bakelite, invented in New York in 1907, by Leo Baekeland, who coined the term “plastics”. Dozens of different types of plastics are produced today, with many consumers interacting with common plastics like polyethylene, which is widely used in consumer packaging, and polyvinyl chloride, used in construction and pipes because of its durability and strength. Many chemists have contributed to the materials science of plastics, including Nobel laureate Hermann Staudinger, who has been called “the father of polymer chemistry” and Herman Mark, known as “the father of polymer physics”.

The success and dominance of plastics starting in the early 20th century causes widespread environmental problems, due to their slow decomposition rate in natural ecosystems. Toward the end of the 20th century, the plastics industry promoted recycling in order to assuage environmental concerns while continuing to produce virgin plastic. The main companies producing plastics doubted the economic viability of recycling at the time, and this is reflected in contemporary plastic collection. Plastic collection and recycling is largely ineffective because of the complexity of cleaning and sorting post-consumer plastics. Most plastic produced has not been reused, either being captured in landfills or persisting in the environment as plastic pollution. Plastic pollution can be found in all the world’s major water bodies, for example, creating garbage patches in all of the world’s oceans and contaminating terrestrial ecosystems.

WHO

WE ARE?

Metro Plastic Manufacturer Sdn. Bhd. is an established plastic bags manufacturer located in a very strategic location in Perak, Malaysia. Our founder has 30 years of plastic manufacturing experience since the early 90s.

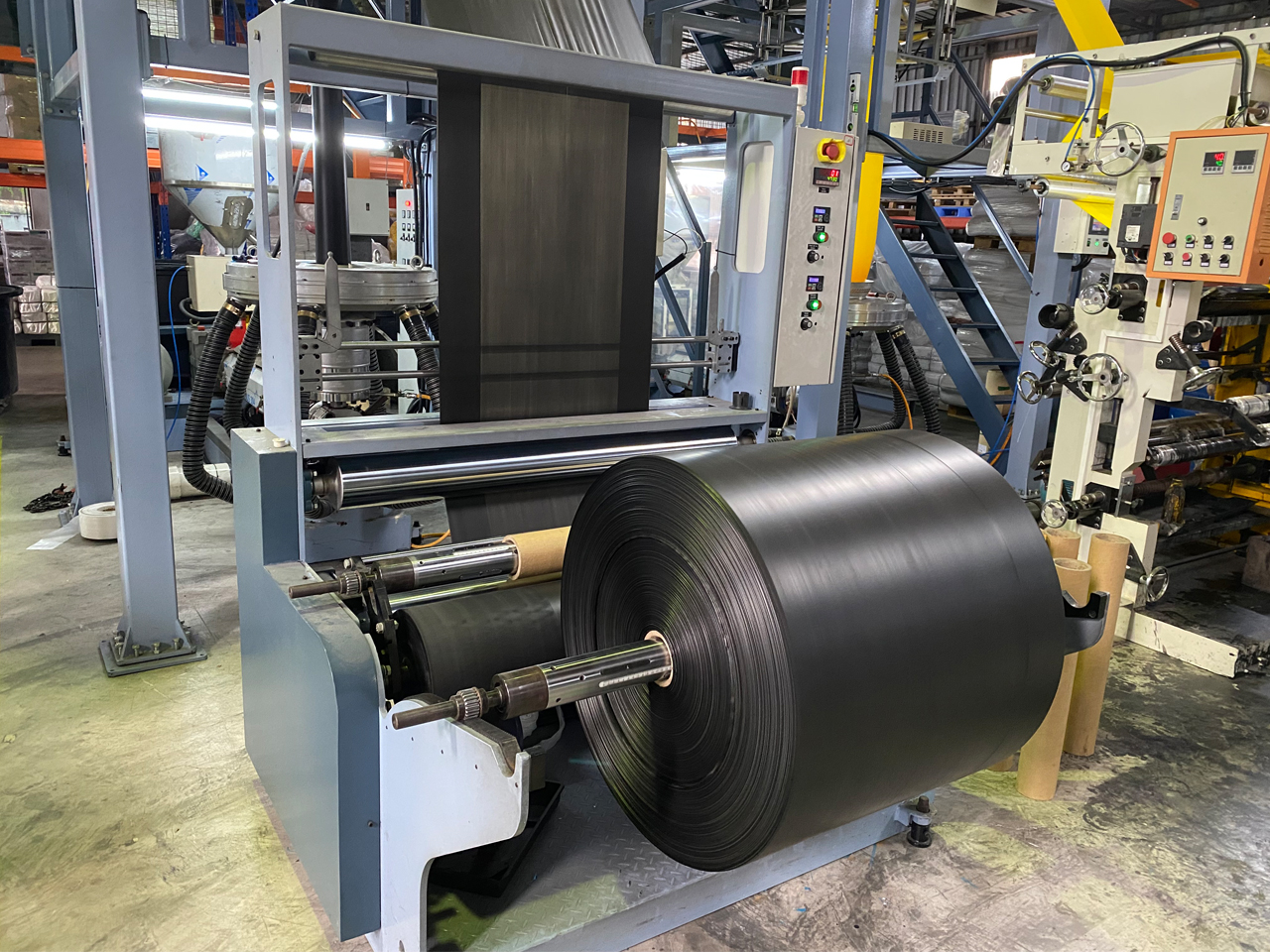

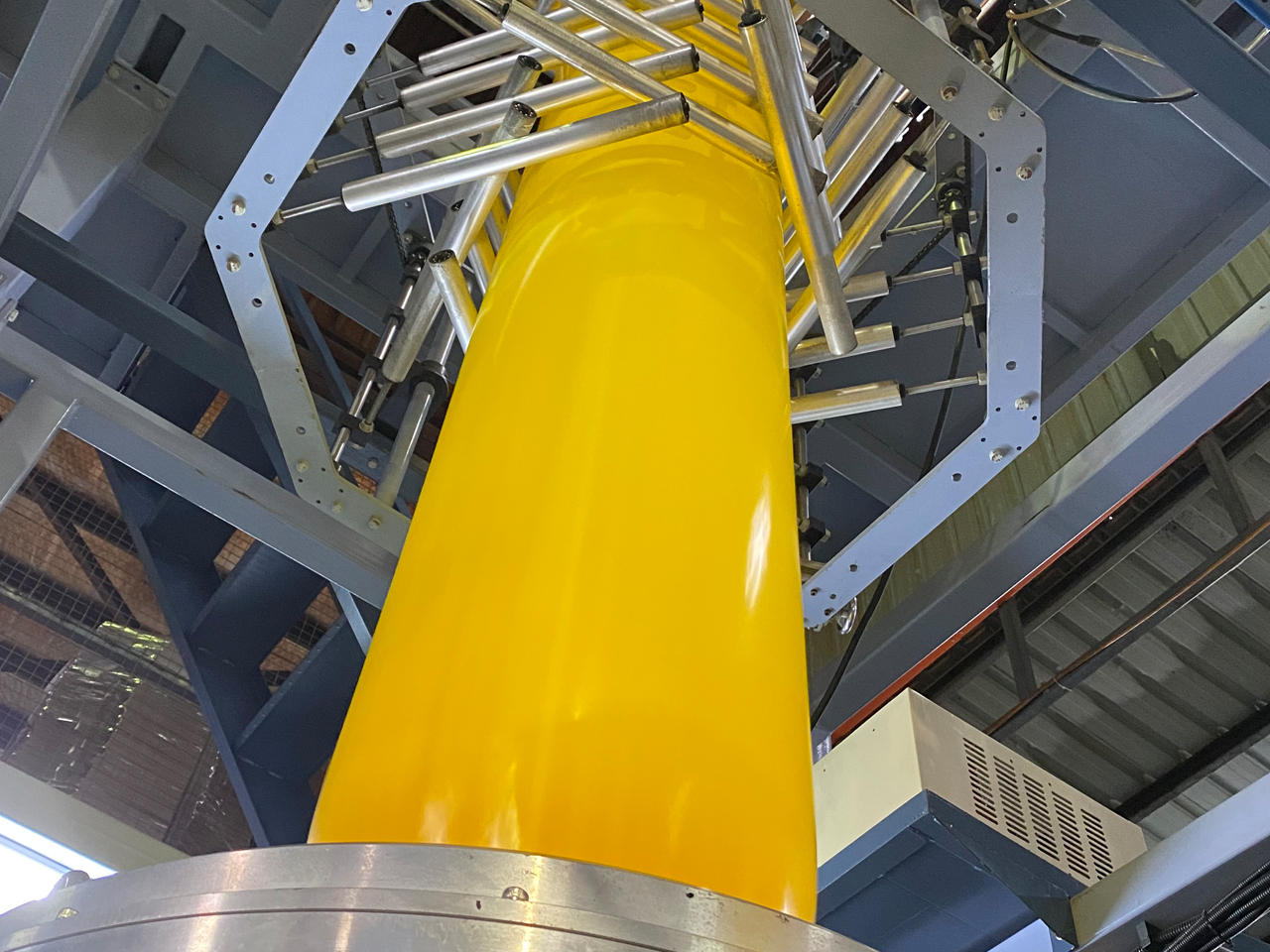

Here at Metro Plastic, we use modern and systematic manufacturing methods with high-tech machineries to maintain our quality, achieve our target and delivery lead time to our customers. A Quality Management System is in place to keep quality of our products in check.

Metro Plastic is also a place where we emphasize on effectiveness, efficiency, quality control and responsible working attitudes to achieve a higher customer’s satisfaction.

Motto

To achieve high efficiency and top quality production.

Mission

To produce the highest quality products at the lowest cost possible.

Vision

To best understand the products & satisfy the clients.